One of the biggest nightmares in e-commerce is making a sale only to realize that the product is out of stock. There are myriad reasons it could happen—outdated spreadsheets, stock wasn’t updated when it was sold from a different marketplace or store, or maybe just human error and no one realized the stock was that low. Regardless of how it happens, it’s crucial in e-commerce to avoid overselling inventory. Here, we’ll explain a few of the best ways to do it!

Ditch Spreadsheets and Sync Inventory

When you first started out, spreadsheets may have seemed like an easy way to manage a handful of SKUs. Maybe you have a shared doc that you and other employees update. This approach, however, leaves plenty of room for human error. People may forget to update. Someone might overwrite someone else’s edits. The sheet may get deleted. The list goes on.

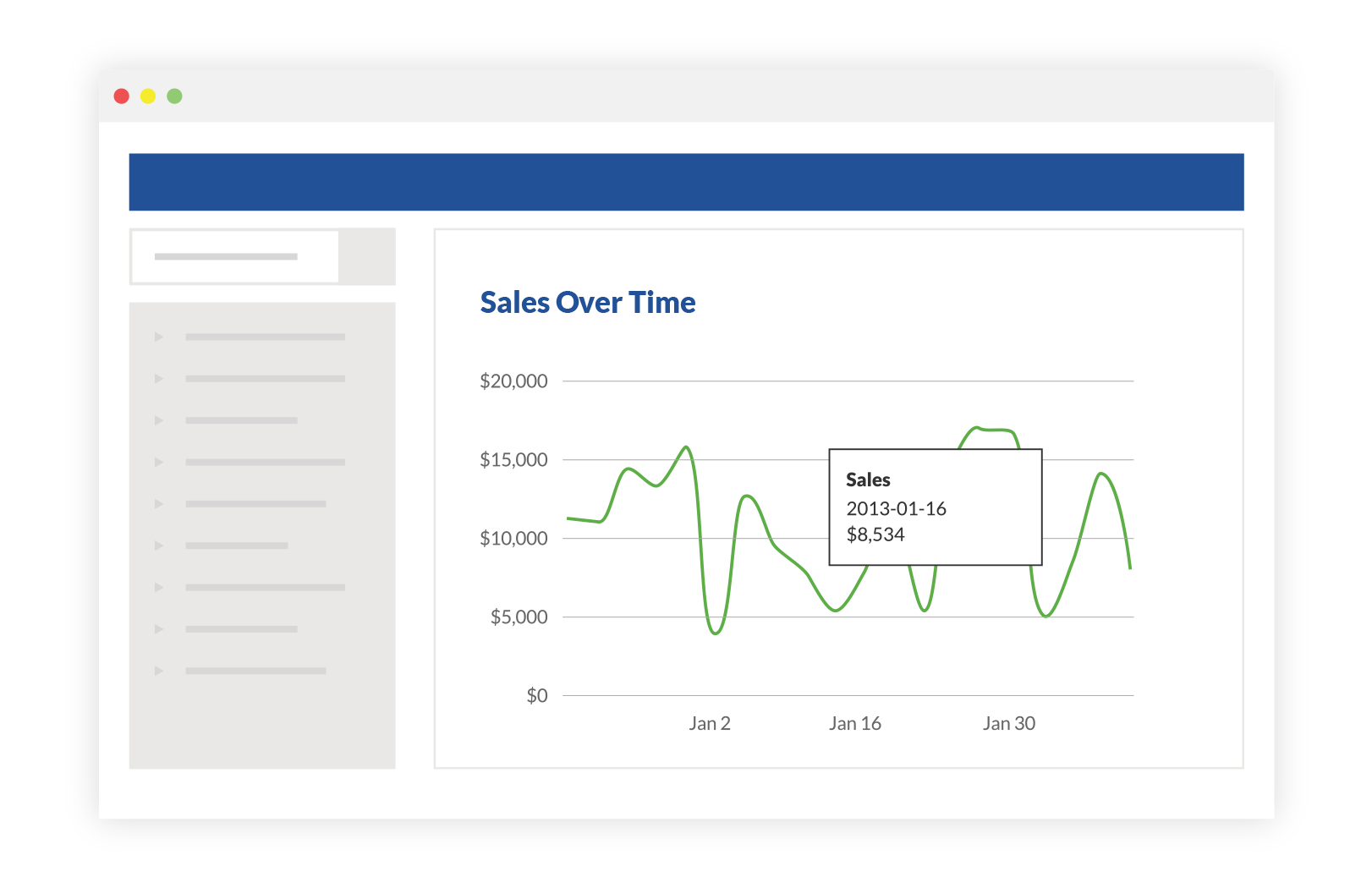

This becomes even more convoluted when you’re dealing with inventory being sold on different sales channels. When you can have all of your inventory levels sync up in a single platform, you can manage everything with ease. Timely and accurate inventory levels mean you never have to end up having the awkward conversation with a customer that they’ll have to wait while you reorder the product they ordered. Spreadsheets simply don’t scale. What does scale is a platform that incorporates robust automation and talks to your sales channels.

Use Low-Stock Alerts

The easiest way to mitigate an issue is to be aware of it. Implementing low-stock alerts will help you avoid overselling inventory by letting you set a specific threshold in your stock that initiates an alert. This can and should be based on your reordering turnaround times. We’ll talk about that more in a minute. A good inventory management solution should allow you to set up low-stock alerts that make sense for your business processes.

Build Velocity and Forecasting Reports

It’s important to know the turnaround times for your products when reordering them from your suppliers. But that’s not the only element that can help you avoid overselling inventory. Velocity and Forecasting reports can help you predict the future in a way. We dive deeper into these two reports in this article, but basically, they are defined as:

Velocity reporting: the rate at which you sell products through your various sales channels. This key report gives you a full breakdown of how fast each product is selling over a period of time. This metric also helps identify your fastest or slowest selling products in order to make business decisions beyond reorder quantities.

Forecasting reporting: demand forecasting uses velocity data to project future sales and help you make smart decisions. Once you have an idea of how many of which products you sell, you have a better idea how many units to replenish.

Velocity and Forecasting reports are like an inventory cheat code. Trends tell you the right amount of product to order and when, so you don’t end up with stagnant products on the shelf or running out of products your customers will want.

See These Tips in Practice

eRockets is a leading seller of high-quality model rocket kits and accessories. There are a lot of SKUs to deal with in that industry and owner Randy Boadway needed a solution that kept up with the needs of his thriving business.

Randy makes full use of low-stock alerts to let him know which items he needs to prioritize reordering, syncs his inventory levels across sales channels, and even creates bundles to make it easier to track items that sell together.

Rob Zaleski

Latest posts by Rob Zaleski (see all)

- USPS 2023 Shipping Rate Changes - November 16, 2023