Where it all began

For thousands of business owners, the 2008 recession had a devastating effect on their business, shuttering many doors of small and local businesses. For others, like Appalachian Organics, it offered an opportunity to pivot.

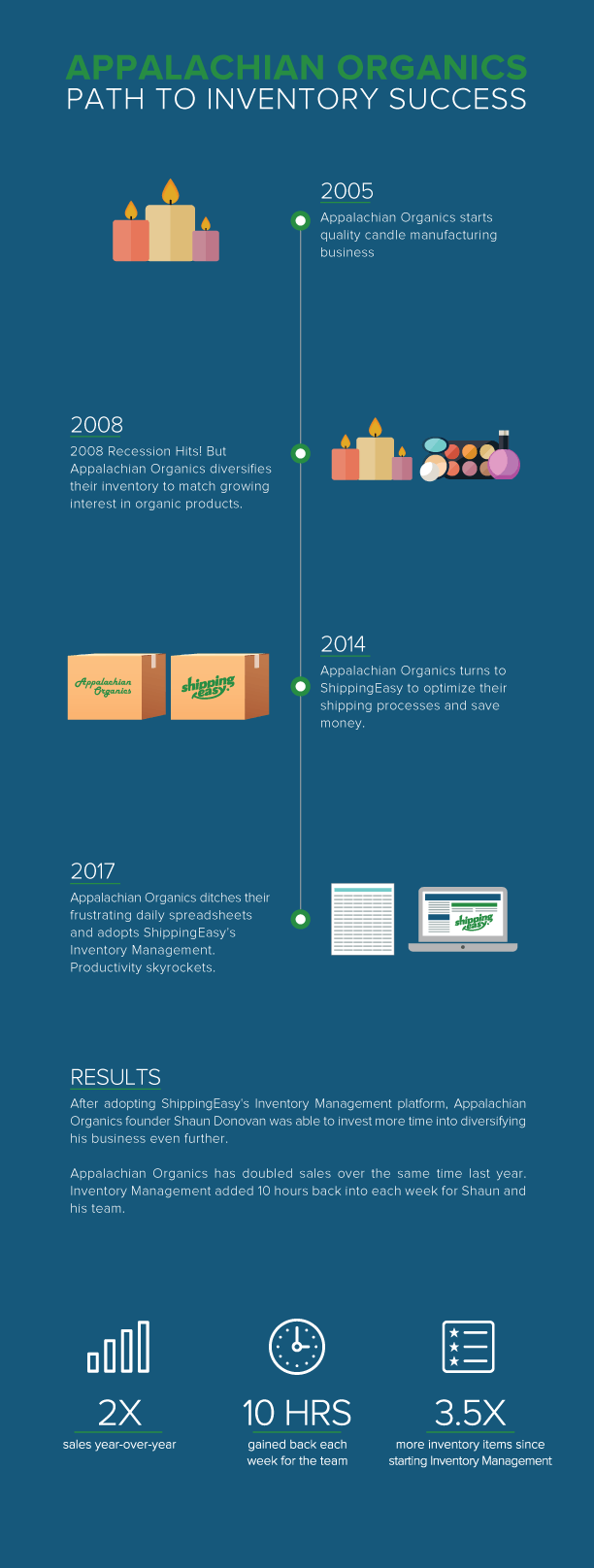

What started in 2005 as a candle manufacturing business, began to diversify into other natural, organic products like soaps, lotions, pet supplies, and foods. Founder Shaun Donovan saw an opportunity to capitalize on the organics industry, and began carrying products that catered to those customers looking for a place that carried all the products they needed.

Through perseverance and tenacity, Appalachian Organics became a trusted source for a niche industry of people following a specific lifestyle. But with all the new inventory Appalachian Organics now carried, Shaun was finding the task of managing it daunting.