Managing inventory replenishment is an age-old problem, one that has existed since the first retailer went into business. The fact is, the inventory you keep on hand is a major investment—one that you need to carefully manage to ensure success and longevity for your company. You need to strike the fine balance between having enough inventory available to meet the needs of your customers and having too much inventory considering the costs such excess entails. This is where inventory reporting comes in.

The tools available to you today, like the latest inventory reporting tools offered in quality inventory management software solutions, make replenishment simpler and more easily managed than ever before. You can not only keep track of your inventory in real-time, but you can also utilize automatic reports and ordering processes to take care of the majority of your replenishment needs—so you can focus your energies on the tasks that only you can handle.

The Importance of Leveraging Inventory Management Software in Decision Making

If you are like most e-commerce business owners, you have your hands full with keeping your company moving forward while avoiding any pitfalls. You may utilize an inventory management solution to help you keep up with the ongoing changes to your inventory and stay organized. But unless you are taking advantage of the inventory reporting options at your disposal, which should be included in your management solution, you will not be able to make the informed ordering decisions you would otherwise.

It is worth learning about the basics of inventory trends and the potential reporting tools you can use to manage ordering decisions. The more you know, the better you will be able to leverage your software to replenish without falling behind or getting too far ahead of customer demand.

Inventory Reporting—Areas to Focus On

The types of inventory information you need to focus on may vary depending on your specific business, but there are some core areas that should be useful for just about any retailer. Keep in mind that the terms used can sometimes differ depending on the software you are using or the school of thought you come from, but the concepts remain fairly consistent.

Some of the most important areas that help with estimating replenishment needs include:

Available Stock

As the name implies, the available stock is the stock you currently have available to fulfill orders. Your inventory management solution should keep an exact count of all of your stock so that anytime you look at the amount of available stock you have, the numbers you see are accurate. Of course, this is made much easier through software—keeping track of even basic information like available stock is much more difficult and error-prone if you attempt to do it manually, such as keeping track of everything on a spreadsheet.

Awaiting Stock

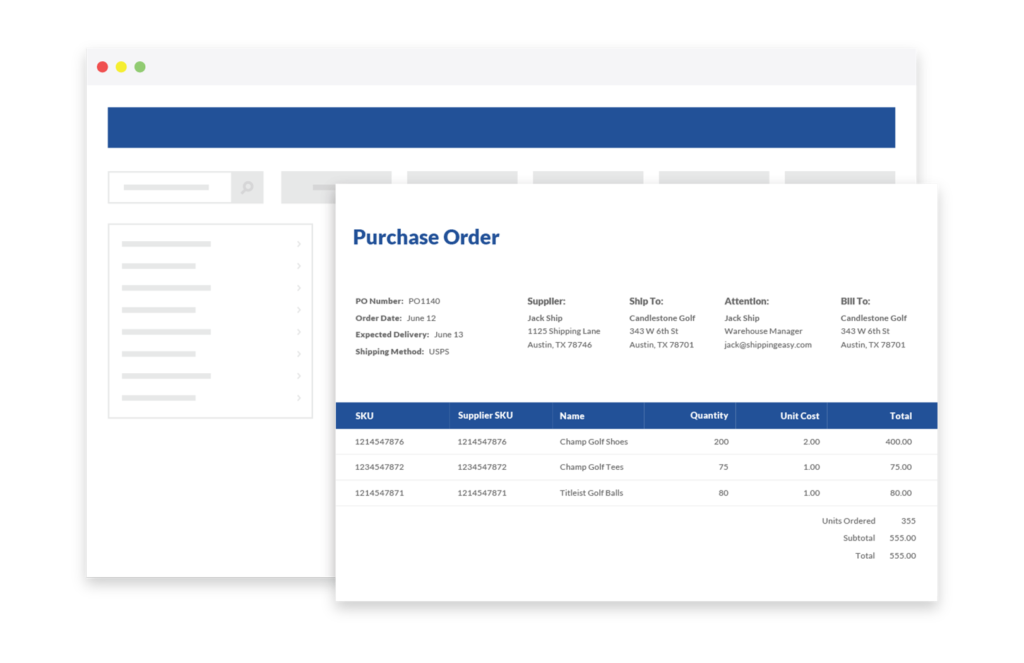

Your awaiting stock is the stock that you have ordered from your supplier, but have yet to receive. The lead time for various stock can differ for all sorts of reasons, including the supplier you use, the product you are ordering, inclement weather, etc. Awaiting stock is so important because it tells what is coming down the line if you were to order nothing else. Failing to take awaiting stock into account will result in over-ordering, which is obviously undesirable.

Lead Time

Every supplier has a lead time that you need to consider—the amount of time it takes from the moment you place your order with the supplier to the time the product arrives at your door. In fact, it is beneficial to look beyond the general lead time you expect from a supplier to the lead time for each individual product. This will give you a clear idea of what kind of lead time is expected before you get exactly what you ordered.

In-Stock Expectation

The in-stock expectation is the percentage of inventory you want to have on hand, either during a certain time period or all the time. Many e-commerce retailers want to have an in-stock expectation of between 95% and 99%, but the number you choose will depend on your individual business needs. This number depends heavily on your cash flow and how much room you have to keep your stock close to full.

Inventory Reporting Tools that Will Help You Make Smarter Ordering Decisions

Once you understand the basic concepts of inventory reporting above, you can go further and use inventory reporting tools to get a clear idea of what ordering decisions you should make. These inventory reporting tools include:

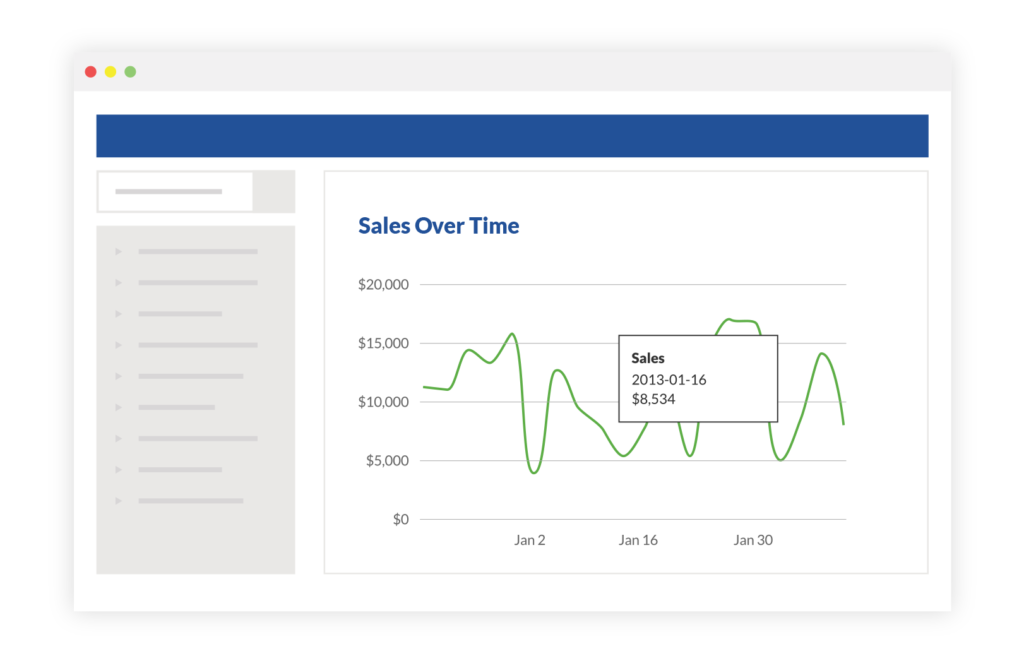

Velocity Reporting

Velocity is a simple calculation used to determine the rate that you sell a product. To determine velocity, calculate how many items have been sold and divide that number by the number of days in the sales cycle. Knowing velocity helps you see the rate at which each product is selling—valuable information that plays a major role in how you determine what to order and when. Knowing your product velocity provides other benefits as well, including the ability to see the products that sell most quickly and most slowly so you can identify areas where marketing may be able to improve velocity.

Forecast Reporting

Forecast reporting uses velocity data along with your projected sales window to predict demand so that you can replenish products before they sell out—without ordering so much that you are carrying more inventory than you want to carry. Factors that are considered when forecasting include:

- Velocity – Rate at which items are sold over a specific time period

- Available Stock – Stock currently on hand

- Awaiting Stock – Stock currently on order from suppliers

- Forecast Period – The time frame included in the calculations for restocking

- Stockout – How many days a product can be sold before it runs out

- Lead Time – How long it takes for a product to arrive from the supplier after ordering

- Reorder Period – When a product must be reordered so that it arrives before available stock runs out – or stockout

- Lead Demand – How many products will sell based on the current velocity figures in the amount of time an order will take to arrive

How Your Inventory Management Software Can Automate Replenishment Based on Reports

While it is always a good idea to check inventory reports regularly, there is a lot to be said for the convenience of automation. A robust inventory management program will be capable of automating not just the reporting process, but much of the replenishment process as well.

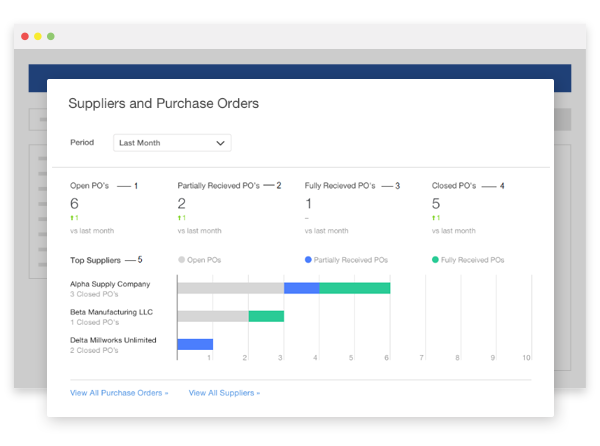

Using velocity reporting and forecasting, your software should automatically provide you with the information you need to make smarter purchase decisions. You can rely on certain software to see how much stock is on hand, how much has been ordered, what rate of sales can be expected, and how soon stock needs to be ordered. This information lets you place the order during the reorder period so you can avoid being out of stock when a customer places an order. Best of all, the software will constantly be updating reports and forecasts, so orders are managed in real-time.

Rob Zaleski

Latest posts by Rob Zaleski (see all)

- USPS 2023 Shipping Rate Changes - November 16, 2023