The busy holiday season is right around the corner—which means it’s the perfect time to review some inventory management best practices. The better you can incorporate habits and tools that make business easier, the more easily you will be able to adapt to whatever the coming quarter throws at you.

We have curated some of our favorite tips & tricks here so you decide how you might be able to apply them to your business. Read through them and use works best for your business.

Hit the 4th Quarter Running—Best Practices for Your Inventory

1. Make pick and pack work for your specific business.

You have probably heard of how important pick and pack procedures are for efficiency and accuracy when fulfilling the orders customers send your way. There are four different processes to note, including zone picking, batch picking, discrete order picking, and wave picking. Let’s first break down what each of these means:

- Zone picking: A method of order picking that involves dividing SKUs into a series of different zones with each warehouse employee trained to pick within an assigned zone.

- Batch picking: Also known as multi-order picking, this is characterized by combining product demand from multiple orders into one pick instruction. After order picking, products are sorted/consolidated by order or shipping destination.

- Discrete order picking: A method of picking orders in which the items on one order are picked before the next order is picked.

- Wave picking: An application of short-interval-scheduling to support organizing of the daily flow of work of a warehouse (i.e. picking in waves).

If you want to improve the way you use these processes, consider taking the following steps:

- Make sure to regularly organize your warehouse by keeping it clean and eliminating clutter periodically.

- Think carefully about how your warehouse is set up to avoid wasted movements and lost time. For instance, the items that you ship most often should probably be closest to the packing station.

- Counting accuracy is vital, so implement a system where each order is checked at least twice.

- Utilize a warehouse management system that makes things easier for everyone on and off the floor—like listing items in a way that pickers can find them without backtracking.

- Barcodes are your friend, so make sure that all items have them or have RFIDs.

2. Try to always have a bit of safety stock available.

Lead times and market demand can make it challenging to have items on-hand when you need them. The challenge becomes a little easier to manage when you keep safety stock inventory. You don’t need a lot of it, necessarily, but you should have some. Otherwise, you risk losing out on customers and revenue.

Safety stock inventory does require more investment, but it also brings benefits that include avoiding stockouts, helping you weather inaccuracies in market forecasts, buffering against surges in demand, and allowing you to deal with lead times that turn out to be longer than desirable.

By telling your inventory system how much to deduct from your actual quantity, your numbers should be adjusted automatically when you receive stock from your purchase orders. Couple this with low-stock alerts and you’ll never have to worry about running out of an in-demand product again!

3. Improve your stocktaking process.

While stocktaking is not always something you want to do, the fact is that counting your inventory is a necessity. Human error is sometimes unavoidable, but there are several things you can do to minimize it and ensure that all the time you spend counting inventory delivers maximum benefit to your business.

Take a look at your stocktaking process and verify that you include the following steps:

- Get the stockroom cleaned up and organized before you begin counting.

- Count every single item, including those inside boxes. You cannot afford to miss anything.

- Make sure you are aware of what kind of stock you are counting and that you have a clear idea of how you are counting it.

- Leave time to count—preferably by scheduling the process in a way that keeps it from getting in the form of regular business.

- Streamline the stock counting process and remove the element of human error as possible by implementing an inventory management solution.

We’ve heard many stories of business owners manually updating shared spreadsheets, often times with multiple people managing the sheet. When you don’t have much inventory, this can possibly work. But once you have multiple products, multiple locations your product lives, or multiple places you sell, you’re better off automating the process as much as possible.

4. Decide what kind of inventory management works best for your business.

Every business has a way of doing things—which means that some inventory management practices are more applicable to certain businesses than others. You may need to implement some practices and avoid implementing others to create an optimized system for your company. For example, most businesses benefit from implementing either periodic reviews or continuous reviews.

With a periodic review, you choose how much of each product you need at the beginning of specific time periods. Once the time period is coming to an end, you count how much of each product you have left and determine how much you need to order for the next period. What you order is determined by what you used and what you expect you will need—not some set amount determined earlier.

A continuous review process instead has a set amount of items that will be ordered with every order. You need to keep monitoring inventory levels to ensure that none drop under a certain point. Low stock on an item will indicate you need to place another order.

By taking a look at how you do business and considering the advantages and disadvantages of each system, you can choose the one that will best serve your needs.

5. Take full advantage of automation.

Inventory management has come a long way from what it once was, with many businesses able to automate vast sections of the process. Automation minimizes the cost of labor and increases the accuracy and control you can exercise over your inventory.

There are many, many ways you can automate your inventory—some of which may be more appropriate for your business than others. One of the most common automation methods used is automatic identification and data capture (AIDC). It allows you to ID every item that comes through your warehouse and keeps that information updated and organized in real-time. Having employees equipped with barcode scanners means that just a few workers can continuously update and access the database with the press of a trigger.

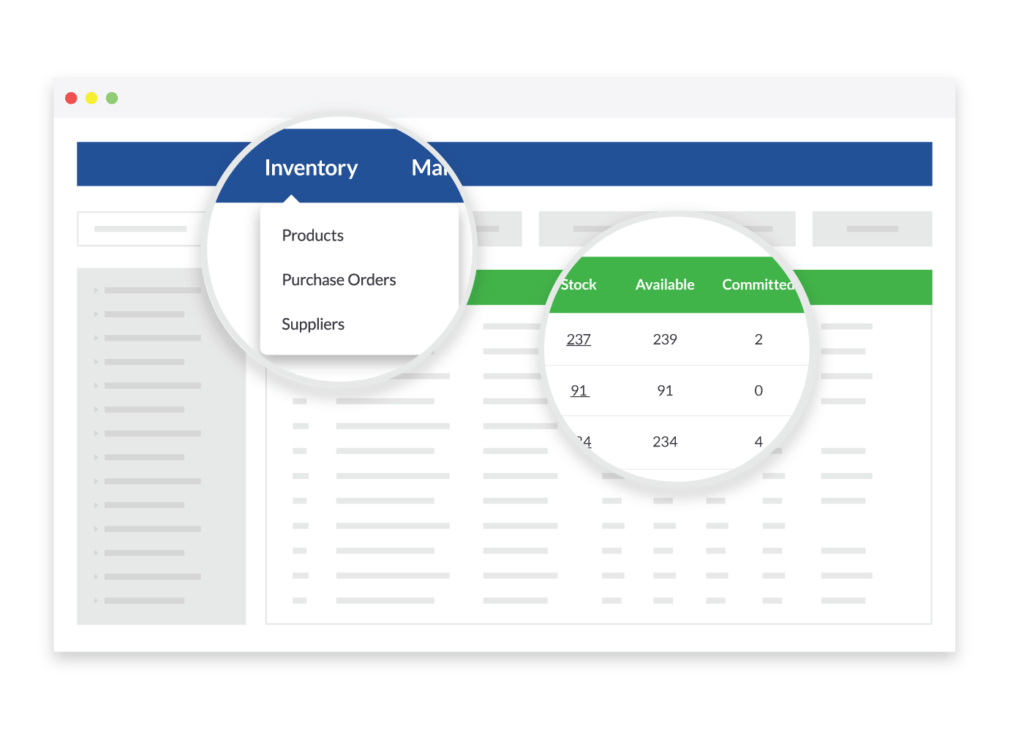

6. Update your management system to the cloud.

A cloud-based inventory management solution offers all the advantages of standard Excel inventory management systems while eliminating many of the disadvantages. Because you can manage your inventory from anywhere, cloud-based systems can allow your business to be more agile. This also gives you the advantage of allowing others to log in and manage purchase orders, suppliers, and inventory levels from a business office, warehouse, or even an airport terminal!

Another major advantage of cloud-based systems is that they are constantly being managed and upgraded as necessary to add more features. They do not become outdated because they are regularly improved. And if you do need help or information, you only need to contact your service provider to get expert advice and support.

7. Keep up with quality control.

The fight to maintain your desired level of quality is one that you will continue to wage for as long as you are in business. Quality control is one of the foundations of a successful company, so it makes sense to push your team to ensure that quality is always maintained.

There are a variety of ways you can create a quality control system based on what is most important to you and your customers. Many businesses have employees keep a checklist to guide them in quality control, with steps like checking inventory for signs of damage and verifying the accuracy of orders.

Once you decide what quality means it is not difficult to develop a checklist that will ensure that your standards are maintained. This will be especially important to dictate before the rush of holiday season hits, and you’re left trying to keep up with the demand.

8. Prepare for maintenance ahead of time.

In the push to grow your business, it can be easy to forget that every piece of equipment has a limited lifespan. Repairs, maintenance, and replacement are all necessary eventually. Instead of dealing with these issues as they pop up, you can account for them in your inventory management processes.

Someone with the right expertise can forecast when your equipment is likely to need fixing or replacement. With a solid forecast, you can work in ordering replacement parts, integrating downtime for repairs, and any other possible hiccups that you know will come eventually.

9. Use your ABCs.

It is always helpful to organize your inventory based on what you need and when you need it. ABC analysis lets you put inventory items into basic categories that clarify what level of importance they hold in your overall business processes.

Items in the A category are the most important ones that you carry. They tend to sell quickly and require reordering and ongoing reviews for quality control. Items in the B category are also important and valuable, just not as much as those in category A. B category items most likely need to be ordered monthly. C category items are lower on your priority list, and they may be ones that you keep a large quantity of, reordering irregularly.

10. Find the sweet spot with your inventory—not too much, not too little

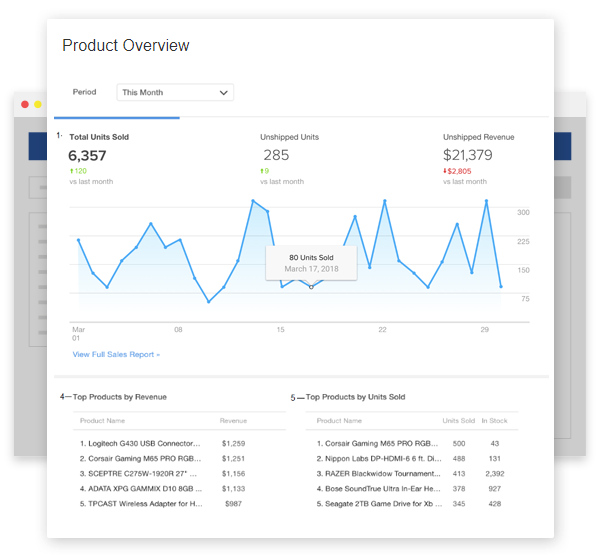

Identifying the sweet spot where you always have enough inventory but do not get overburdened with too much inventory, comes with time and regular analysis. Pay attention to the flow of your inventory and take regular notes. Better yet, use automatic tracking to give yourself data points you can analyze throughout the year. Projecting your future sales and inventory needs using past trends is easy when you have the data at your fingertips!

Try to review this information each quarter when planning how to manage your inventory in the future.

ShippingEasy integrates with many inventory management solutions. We help you manage your orders and automated your shipping, so you never miss a beat. Get started for free by clicking below!

Jack Ship

Latest posts by Jack Ship (see all)

- E-Commerce Shipping Solutions You Should Consider for Your Site - February 28, 2021