Growing e-commerce merchants are always looking for strategies and tools that will help them continue on their growth trajectory. When those merchants are juggling orders and inventory from multiple sales channels, things can get complicated in a hurry. The right inventory management software can help alleviate some of those complications. Let’s take a deep dive into what makes for a quality inventory management solution and how it can affect your business.

Table of Contents (click to jump to a section)

- What does e-commerce inventory management software do?

- Who is inventory management right for?

- Important inventory management software features

- Purchase Orders and Supplier Management

- Creating Bundles

- Integrations With the Places You Sell

- Support: the Unsung Hero in Inventory Management

- Take the Time to Vet Software

What does e-commerce inventory management software do?

Once you start selling on multiple online platforms and channels, your day-to-day can become a bit complicated. One improper calculation of your inventory can cause hours, days, or even weeks worth of hassle, not to mention the customer service nightmare, and it can affect customers across your selling channels.

Inventory management software lets you simplify and streamline your inventory processes. At its core, it helps you quickly and easily tally your stock. But many inventory management solutions do much more than that. Let’s go over some features you should look for in a quality solution and how you should be evaluating solutions.

Who is inventory management right for?

Many sellers begin managing inventory through spreadsheets. It’s easy, you can set up formulas to calculate numbers, and you can easily share it in a Google Drive or other folder with other staff. We see this approach often and it’s a great way to familiarize yourself with managing your stock. It isn’t sustainable, however.

Any time you have a human, or multiple humans, manually keying in quantities, it leaves room for errors. Let alone when you’re doing this across multiple sales channels or storage facilities. Things can get out of hand in a hurry.

As your business continues to grow, and you add additional staff and sales channels, your inventory becomes much more complicated. You need something that will grow with you, adapt, automate your processes, and remove the opportunity for errors. That’s what a quality inventory management software solution does.

So who can benefit from using inventory management software? Anyone who sells things—and that’s you.

Important inventory management software features

As you’re beginning your search, it’s important to have a solid grasp of exactly what a robust inventory management platform should encapsulate. Some features may be more important to you than others, but having a handy list of what to expect can help narrow your search. So what features should you look for in an inventory management software?

Inventory Automation

To gain an edge and remove much of the headache of managing your inventory, automation will be a key benefit of an inventory management software solution. When an item sells on one channel, say your Shopify store, your inventory management platform can update the in-stock quantity on your Amazon or eBay store to make sure your quantities match across the web. When you aren’t doing this process manually, you can feel more confident in the quantities you have on-hand, and thus make smarter reordering and sales decisions.

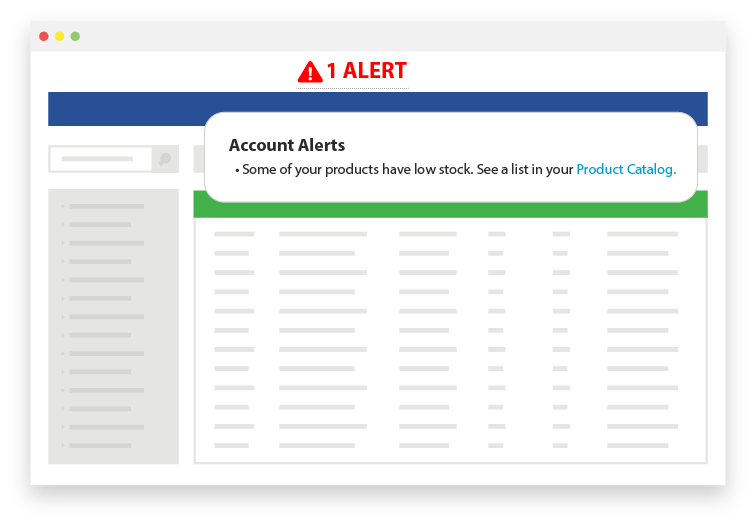

That is just one part of the automation, however. The ability to set up low-stock alerts will help you avoid stockouts. This is particularly helpful if you can set low-stock alerts on a per-product basis. If you have multiple vendors in varying locations, you can take into account turnaround and typical delivery time to refrain from wasting shelf space while still avoiding stockouts.

Low-stock alerts can be automated to alert you when you’ve reached your threshold.

Inventory stock levels tracking

The most obvious element of inventory management software is tracking your stock levels. Your inventory management software should have a product catalog that allows you to adjust quantities, change product information, assign categories and SKUs, create variants, and more. As you continue to differentiate your inventory, you’ll need more and more ways to disambiguate products to ensure 100 percent order accuracy.

As previously mentioned, this can get complicated when you have multiple sales channels and may need to create alias SKUs across them. Look for a solution that allows you to easily import your SKUs and stock from your store and marketplace settings. You should then be able to send information back to those channels to ensure accurate quantities across every store and marketplace. When you have a central hub of information sending out updates, your stock numbers are much more reliable.

An often overlooked aspect of managing your stock levels is using what is called “safety stock.” Safety stock pads the numbers a bit to make sure the quantity you have on-shelf or in the warehouse is always just a few more than what your selling channels show. This gives you the opportunity to fulfill orders when sales happen to surge without having to send a dreaded out-of-stock email to a customer.

Inventory reporting

Every good business owner runs reports to keep tabs on the business. This is especially true for inventory management in many ways.

First, reports give you a crucial look backward to understand sales trends and analyze stock. They allow you to filter by low-stock quantity products to understand what’s most pressing to reorder. These reports can tell you how much stock you have committed to orders and give you an idea of how quickly items may be running out.

Second, inventory reports can help you predict the future. By using Velocity Reports, you can not just see how much you sell, but at what rate over time you sell products. With that information, you can create Forecasting Reports to make smarter decisions around how much stock to order to get you through a specific period of time, even taking into account travel time from the supplier to your warehouse or office.

Top inventory management software solutions also allow you to automate and schedule these reports to make sure you have them ready on a regular cadence. You can export these reports and use them to make smarter inventory planning decisions.

An at-a-glance dashboard may be a nice-to-have for some, but the faster you can access data, the better. Having instant access data to your top-selling products, trends over time, and other sales data can help you make quick decisions when you need to. Ask about what kind of overviews and dashboards are available to you in any inventory platform you’re considering.

Purchase Orders and Supplier Management

Your relationships with your suppliers can be just as important as your customer relationships, if not more so. It’s crucial you have the most up-to-date and thorough information to ensure that you are never delayed when ordering your inventory.

You need to be able to quickly and easily add new supplier information, edit existing information, add tags and notes, note payment terms, and add a tax ID, for example.

Purchase orders are the key piece in your communication with your suppliers, but they can be tedious and time-consuming.

ShippingEasy integrates with some top inventory solutions to make your life easier. Start your 30-day free trial today!

Sometimes, items get delayed and you only receive part of your order. This shouldn’t prevent you from being able to receive the stock that has shown up, but not all inventory management solutions allow you to receive partial stock. Choose the wrong one and you’re stuck with unaccounted inventory until the rest arrives. That’s just inefficient, so make sure you choose one that has the flexibility to work with these kinds of situations.

Creating Bundles

A great way to move more inventory is to bundle products together. But this can cause inventory headaches when trying to account for each item while selling them together. The inventory management software you choose should allow you to bundle multiple SKUs into one while still deducting the available quantities from each individual product. You can then sell more without the headache that would accompany trying to manage multiple SKUs from a single sale.

Integrations With the Places You Sell

This may seem like an obvious one, but there are plenty of inventory management solutions out there that may not fully support some of the most popular selling channels. You likely plan to grow your business, and if your inventory solution doesn’t grow with you, you’ll be doing this all over again down the line.

If you sell or plan to sell on Amazon, you’ll want to look for an inventory management software solution that provides full support of Amazon’s various options: Seller-Fulfilled Prime, Fulfillment by Amazon, and Multichannel Fulfillment. Selling on Amazon is definitely an option you may explore when trying to reach new audiences, so you’ll want your inventory management platform to be ready when you do.

Support: the Unsung Hero in Inventory Management

Inventory is a complicated element of your business, and any time you can implement expert help setting it up, you’ll be better for it. Make sure to ask the sales rep or implementation engineer what kind of support is offered with their service. Some will leave you to your own devices, and some will only offer limited options.

Take the Time to Vet Software

You may just want to jump in and get it over with, but that could be a mistake. Look for solutions that offer free trials so you can dip your toes in, get set up, and test out the full functionality to make sure it will work for you. Whatever software you choose is going to vastly affect your day-to-day operations, so you don’t want to rush into a decision.

Write up a checklist of the specific needs you have to make sure you keep them all top of mind and talk them over with a solutions engineer or sales rep. You may even prioritize them as far as must-haves versus nice-to-haves. Some solutions may fit your must-haves so well that you may be willing to forego the other features (or potentially put in feature requests that your software provider to put into their software development queue).

As you do your research, consider one that integrates with ShippingEasy to make your life exponentially easier. Click below to start a 30-day free trial of our shipping and order management software!

Rob Zaleski

Latest posts by Rob Zaleski (see all)

- USPS 2023 Shipping Rate Changes - November 16, 2023