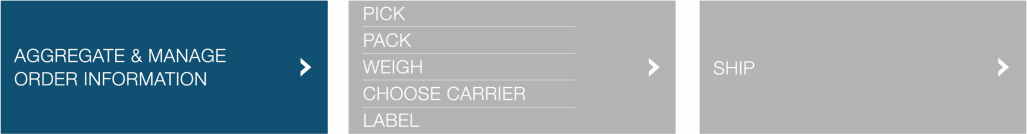

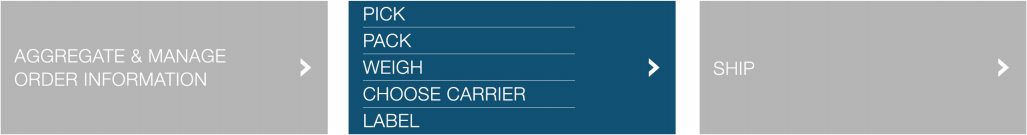

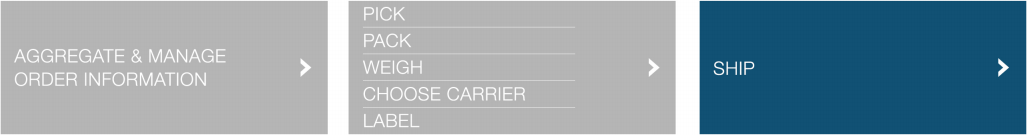

Shipping Process at a High Level

The capabilities you choose to implement will inform the processes you follow—as well as the technology you select. While there are hundreds of subtle process permutations based on the capabilities we’ve covered, here are the common high-level steps.

1. Aggregate and Manage Order Information

Getting the order information from your selling environment(s) into your shipping environment and preparing them for shipment. Including, but not limited to:

- Validate addresses

- Confirm inventory

- Check customer and internal notes

- Combine orders from the same customer

- Split orders going to multiple addresses

- Assign orders to categories

- Apply rules/mapping

- Mark as drop shipped

- Sort and/or filter orders by:

- Warehouse location

- Number of items

- Order date

- Weight

- Domestic/international

- Residential/commercial

- Other attributes relevant to your process

- Manage inventory and communicate levels to selling platform

Basic functionality: No shipping platform available

In the most basic shipping environment, there is no shipping platform—everything tends to be managed via the selling platform(s) and the carrier’s website (e.g., UPS Worldship or FedEx Shipment Manager) or PC Postage provider (e.g., Stamps.com or Endicia). In this case, you would simply log into your selling platform (into each one, one at a time, if there are more than one) and print your packing slip(s), then move to the next step. In some selling platforms (e.g., eBay, Amazon, Etsy), labels can be generated directly from that platform for orders generated there.

Advanced functionality: Shipping platform available

In this case, your shipping platform receives the order data via the Application Programming Interface (API—a software interface that allows one system to easily send and receive data from another system) from the selling platform(s) in real time, including the customer-selected shipping option, customer address, customer messages, order split/merge information, and item weight and dimension measurements, when available. If multiple selling platforms are used, a good shipping solution can aggregate order data from all of them into a single view.

- Your shipping platform updates inventory levels based on order data received from selling platform and actual shipment

- To guide automated processes, shipping administrator(s) can manage order data by filtering and sorting

- Multiple administrators can view and manage specific groups of orders, communicate with each other, and collaborate to prep orders for picking, packing, and shipping

- Your shipping solution applies rules to order data to automate decision-making and repetitive tasks

- Your shipping solution creates related pick lists, packing slips, and shipping labels, and readies them to print. A good shipping solution allows you to design your pick lists, packing slips, and mailing labels to lay out various data elements from the shipping platform

2. Pick, Pack, Weigh, Choose Carrier, Label

The order in which you complete these steps depends on whether you have shipping measurement data (item weight and possibly dimension) associated with each item and the ability of your Shipping Platform to apply rules to this data to determine the preferred carrier. If shipping measurements/parameters are available and the calculation is feasible, your Shipping Platform may be able to select the best carrier and generate the shipping label while you point the pick/pack lists, pick, and pack. If not, you will need to print the pick and pack list, pick, pack, weigh, and then select the best carrier. So, the big difference is whether you need to stop and weight every package as part of your process or not.

Potential factors influencing this process:

- Average daily order volume

- # of SKUs: Quantity of products on hand/shipping

- # of items: In average order

- Item weight accuracy and availability in store platform

- # of shippers

- # of carriers

- # of printers

Basic functionality: no shipping platform available

- User takes pick list printed from selling platform and uses it to pick item(s)

- User packs items into appropriate box using appropriate materials creating a ready-to-ship package

- User manually weighs and measures package

- User copies customer address from selling platform into carrier or PC postage website

- User enters shipping parameters for package into selected carrier’s label-generation webpage, compares available rates/delivery speed, and selects best carrier/service level

- User prints and affixes label to package

Advanced functionality: shipping platform available

- Shipping parameters, including order weight, have most likely processed in last step as part of the API download process from the selling platform

- Shipping platform (with some level of input from shipping administrator) performs rules-based assignment of shipping box/envelope/polymailer and adjusts order’s weight based on this assignment

- Shipping platform determines best carrier based on shipping parameters (weight, dimensions, customer-selected shipping option, address type, etc.) then generates shipping label

- Alternatively, shipping platform maps orders/shipments to carrier and service based on shipping rules, or

- Shipping platform may offer predictive analytics to assign carrier and service selections based on historical patterns

- If multiple distribution locations exist, a good shipping platform can organize orders by location so pickers at each location can easily select and print their specific pick lists onsite

- Shipping platform routes shipping labels (and packing slips) for a batch of orders to the appropriate printer based on the selected carrier, then it prints labels. Labels (and packing slips) should print in a predictable order based on:

- Order number

- Sequence that an order was selected in shipping platform

- Sequence the order appeared in a batch

- Product SKU

- Product name

- Shipping platform updates selling platform in real time (via API or other data exchange channel) with:

- Carrier tracking information

- Order status updated (“shipped”)

- Inventory level changes

- User packs boxes from bins, checks against packing slip, and affixes sequential labels in an assembly line

Shipping process flowcharts:

Useful visuals for setting up workflow

- Shipping process flowchart: basic with shipping solution

- Shipping process flowchart: advanced process with weight in selling platform

- Shipping process flowchart: advanced process without weight in selling platform

3. Shipping Out Orders

Transfer packages(s) to selected carrier(s) and update shipping information to all parties:

- Order status updates in Selling Platform(s) (e.g. mark as shipped)

- Carrier tracking # update in Selling Platform(s)

- Shipment confirmation with tracking # emailed to customer

Basic functionality: no shipping platform available

- User drops off or places package in pick-up area for selected carrier

- Daily shipment report is delivered to private carrier: End of Day form and electronic package level detail (PLD) report is printed for private carriers (UPS/Fedex) from carrier website

Advanced functionality: shipping platform available

- Assembly line routes each package to appropriate pick-up area for its selected carrier

- Daily shipment reports are automatically generated or delivered to carriers:

- Shipping platform automatically sends all shipment information to private carriers (UPS/FedEx) as labels are created

- User generates a USPS Scan Form for that day’s shipments from the shipping platform and prints for USPS pickup

- Shipping platform monitors physical inventory levels and flags need for replenishment when low inventory threshold is reached

Related Articles & Resources:

- Shipping fulfillment: Processing your Orders

- Shipping fulfillment: Picking & Packing Process

- Shipping fulfillment: Advanced process flowchart

- Integrating Order Data Across Platforms

This article is from The Definitive Guide to eCommerce Shipping

Request a Demo